How Wisconsin Aluminum Foundry ensures precision and reliability

Revealing the Advantages and Practical Utilizes of Aluminum Castings in Today's Market

Light weight aluminum castings have ended up being increasingly relevant in numerous industries as a result of their distinct features. Their lightweight nature and resistance to corrosion make them appropriate for requiring applications. Additionally, the remarkable strength-to-weight ratio supplies considerable benefits in design and manufacturing. As markets proceed to explore their possibility, the full scope of aluminum spreadings' benefits and applications stays to be totally uncovered. What exists in advance for this versatile material?

The Lightweight Benefit of Aluminum Castings

Although many materials are utilized in production, aluminum spreadings attract attention primarily due to their light-weight residential properties. This particular makes aluminum spreadings an appealing choice for numerous industries, specifically in aerospace and auto applications, where weight decrease is important for enhancing gas effectiveness and performance. The lightweight nature of aluminum enables manufacturers to develop elements that are easier to handle and set up, eventually reducing labor expenses.

In addition, the ability to produce complicated forms without considerable weight charges makes it possible for designers to introduce while maintaining structural honesty. Aluminum spreadings can effectively change much heavier products, causing substantial financial savings in delivery and operational prices. Their light-weight benefit also adds to boosted item durability, as lighter elements frequently result in minimized wear and tear on machinery. Overall, the lightweight residential properties of light weight aluminum castings provide makers with an affordable edge, promoting innovations in product layout and effectiveness throughout numerous markets.

Remarkable Corrosion Resistance

Light weight aluminum spreadings have an all-natural resistance to oxidation, which greatly enhances their durability in numerous atmospheres. This integral residential or commercial property not only adds to their resilience yet likewise aligns with the lightweight advantage that light weight aluminum supplies. As an outcome, light weight aluminum castings are significantly recognized for their exceptional deterioration resistance in countless applications.

Normally Immune to Oxidation

Among the standout characteristics of aluminum castings is their extraordinary rust resistance, which stems from an all-natural oxidation process. When exposed to air, light weight aluminum responds to develop a thin, safety layer of aluminum oxide. This layer works as a barrier versus additional oxidation and safeguards the underlying metal from harsh components such as wetness and salts. Unlike other steels, this oxide layer is self-repairing; if damaged, it promptly reforms when exposed to air. This special residential property enhances the long life of aluminum spreadings in numerous settings, making them perfect for applications in sectors such as aerospace, vehicle, and marine. Consequently, the natural resistance to oxidation substantially lowers upkeep prices and increases the reliability of aluminum spreadings in demanding problems.

Lightweight Sturdiness Advantage

The light-weight nature of light weight aluminum spreadings adds greatly to their longevity, making them a useful option in different industries. This remarkable longevity is greatly attributed to aluminum's inherent resistance to rust, which is enhanced even more via anodizing and various other surface treatments. Unlike lots of steels, light weight aluminum does not rust; instead, it develops a safety oxide layer that guards it from ecological damages. This residential or commercial property is especially valuable in sectors such as automotive and aerospace, where weight reduction is vital without jeopardizing strength. Furthermore, the durability of light weight aluminum spreadings lessens upkeep expenses and substitutes, giving financial advantages gradually. As a result, their light-weight sturdiness and corrosion resistance placement light weight aluminum spreadings as an exceptional product for modern-day production applications.

Superior Strength-to-Weight Proportion

A remarkable quality of aluminum castings is their premium strength-to-weight proportion, which makes them highly desirable in various applications. This innate residential property permits light weight aluminum spreadings to hold up against considerable stress and anxiety while staying light-weight, an important consider sectors such as aerospace, automotive, and manufacturing. Designers frequently favor aluminum spreadings for parts that call for both durability and minimized weight, enhancing fuel effectiveness and performance.

The high strength-to-weight ratio likewise helps with the design of complex shapes and structures, making aluminum spreadings flexible for complex applications. In addition, the capacity to preserve structural honesty under difficult conditions assurances longevity and dependability in products, from airplane frames to auto parts. This benefit adds to the expanding fad of utilizing light weight aluminum spreadings in ingenious layouts, ultimately causing enhanced performance and performance throughout diverse sectors. The premium strength-to-weight ratio of light weight aluminum spreadings positions them as a crucial material in modern-day engineering and production.

Cost-Effectiveness in Manufacturing

Cost-effectiveness in aluminum casting production is mainly achieved via decreased product waste and efficient manufacturing procedures. By optimizing designs and using innovative techniques, makers can decrease excess material usage while preserving quality criteria. This method not only decreases production expenses however additionally adds to much more sustainable techniques within the industry.

Decreased Material Waste

Minimizing product waste in light weight aluminum spreading processes significantly improves production effectiveness. By enhancing the style and manufacturing methods, business can lessen excess scrap and boost source use. This decrease in waste not just decreases product prices but also adds to a much more sustainable production version. The ability to reuse aluminum additional supports cost-effectiveness, enabling manufacturers to redeem and recycle products without jeopardizing high quality. As the industry increasingly focuses on sustainability, decreased material waste straightens with ecological goals while concurrently enhancing productivity. Inevitably, effective use of raw materials enhances the competitive placement of services out there, making light weight aluminum castings a beneficial option in numerous applications. The strategic technique to minimizing Discover More waste shows a commitment to both financial and eco-friendly obligation.

Efficient Production Processes

While standard manufacturing procedures can incur substantial prices, aluminum spreading uses an extra reliable option that enhances general manufacturing earnings. This method reduces product waste and enables accurate control over the production procedure, resulting in lowered labor and operational prices. The ability to create complex shapes with less steps additionally streamlines production, contributing to shorter lead times. Furthermore, light weight aluminum's light-weight nature and superb thermal conductivity enable energy financial savings during production and in the last application. By making use of modern-day spreading modern technologies, suppliers can achieve greater throughput without giving up quality. As a result, light weight aluminum casting attracts attention as an affordable remedy, making it an attractive option for services intending to maximize their manufacturing procedures in today's open market.

Adaptability Across Industries

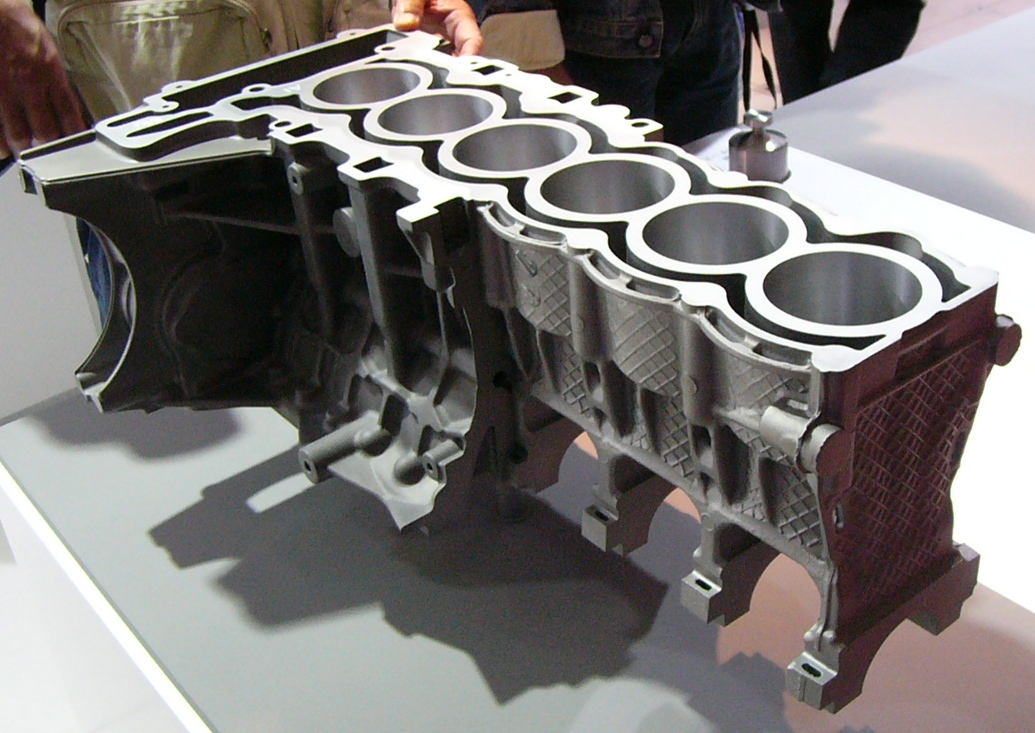

Aluminum spreadings demonstrate impressive adaptability across different industries, as they can be tailored to satisfy certain demands and applications. In the vehicle market, light weight aluminum castings are utilized in engine blocks, transmission real estates, and wheels, offering light-weight yet durable services that enhance fuel effectiveness. The aerospace market also benefits from aluminum castings, using them in architectural parts and engine components because of their strength-to-weight ratio.

In the consumer goods sector, suppliers use light weight aluminum castings for items varying from kitchenware to furnishings, offering both aesthetic allure and performance. The electronic devices industry utilizes aluminum castings for housings and warmth sinks, ensuring efficient thermal monitoring. Additionally, the building and construction field leverages aluminum spreadings for building aspects and architectural elements, enhancing resilience and design versatility. This broad applicability highlights light weight aluminum spreadings as a necessary resource, fulfilling the diverse demands of numerous markets while maintaining high efficiency and dependability.

Sustainability and Ecological Effect

As markets significantly focus on lasting techniques, light weight aluminum spreadings emerge as an environment-friendly selection because of their recyclability and reduced environmental footprint. Light weight aluminum is one of the most go to the website recycled products globally, with the capability to be repurposed numerous times without deterioration of top quality. This characteristic significantly decreases the demand for raw products and energy usage related to primary aluminum manufacturing, which is energy-intensive.

In addition, aluminum castings add to lightweight styles, leading to fuel performance in transport applications such as automobile and aerospace sectors. Their sturdiness and resistance to deterioration expand product life expectancies, additionally lessening waste and resource use in time. Several manufacturers are taking on responsible sourcing and eco friendly manufacturing methods, enhancing the sustainability of aluminum casting procedures. Overall, light weight aluminum castings represent a useful service for companies aiming to decrease their environmental impact while accomplishing performance and efficiency.

Innovations in Aluminum Spreading Technologies

Recent developments in aluminum spreading innovations have actually considerably boosted the performance and top quality of manufacturing processes. Developments such as 3D printing and advanced mold-making methods have allowed suppliers to create intricate styles with reduced product waste. This shift not just boosts the accuracy of cast elements but additionally shortens preparations, permitting for quick prototyping and faster market entry.

In addition, the consolidation of sophisticated computer More Bonuses system simulations aids in anticipating prospective defects throughout casting, bring about higher-quality outcomes (Metal Castings). Using light-weight alloys has actually likewise added to the growth of more powerful, a lot more sturdy products, accommodating markets ranging from auto to aerospace

In addition, automated spreading procedures have actually emerged, lessening human mistake and increasing production speed. Jointly, these innovations are transforming the light weight aluminum spreading landscape, driving better competitiveness and sustainability in production. As industries continue to progress, these modern technologies will certainly play an important function in meeting future demands for effectiveness and high quality.

Regularly Asked Inquiries

Just How Do Light Weight Aluminum Castings Contrast to Other Steels in Terms of Thermal Conductivity?

Light weight aluminum castings display premium thermal conductivity contrasted to several metals, such as steel and iron - Aluminum Foundry. Their lightweight nature and effective heat distribution make them ideal for applications needing efficient thermal administration in different industries

What Are the Typical Flaws Discovered in Light Weight Aluminum Castings?

Common defects in aluminum spreadings consist of porosity, contraction, inclusions, and surface irregularities. These issues usually emerge from inappropriate air conditioning prices, insufficient mold design, or contaminations, influencing the total high quality and performance of the final item.

Can Light Weight Aluminum Castings Be Recycled, and Exactly how?

Aluminum castings can be reused successfully. The process involves gathering, melting, and changing the light weight aluminum, which minimizes waste and conserves sources. This reusing contributes to sustainability while maintaining the product's residential properties for future use.

What Are the Common Lead Times for Aluminum Spreading Production?

Normally, preparations for aluminum casting manufacturing variety from two to 6 weeks, depending upon factors such as complexity, tooling demands, and manufacturing quantity. Effectiveness can improve with well-known provider relationships and maximized manufacturing procedures.

Exactly how Does the Surface Area Complete Affect Light Weight Aluminum Casting Performance?

The surface area coating considerably impacts light weight aluminum spreading efficiency by influencing deterioration resistance, aesthetic high quality, and friction attributes. A smoother finish boosts longevity and performance, while a rougher texture can enhance attachment for subsequent finishes or therapies.

Lots of products are used in production, light weight aluminum castings stand out mostly due to their lightweight buildings. When exposed to air, aluminum responds to create a thin, protective layer of aluminum oxide. Cost-effectiveness in light weight aluminum casting production is mostly attained via decreased material waste and effective manufacturing processes. Lowering material waste in light weight aluminum spreading processes considerably boosts manufacturing efficiency. Eventually, effective usage of raw materials strengthens the affordable position of businesses in the market, making aluminum spreadings a desirable alternative in various applications.